Is your team drowning in repetitive tasks, missed deadlines, and frustrating bottlenecks? This cycle of inefficiency isn't just annoying; it directly impacts your profitability and client satisfaction. Here's a quick win: take one recurring task this week, document the steps, and find a single step to automate or eliminate. This small act is the first step toward reclaiming valuable time. The good news is that you don't have to reinvent the wheel to fix the bigger issues. The solution lies in adopting proven business process improvement methods designed to streamline workflows and eliminate waste.

This article cuts through the clutter to give you a practical, actionable guide to the most effective frameworks available today. We’ll move beyond abstract theory and dive straight into how methodologies like Lean Six Sigma, Kaizen, and Agile can be applied in real-world professional service settings. For each method, you'll find a clear definition, step-by-step implementation guidance, and its specific pros and cons.

Whether you're a freelance designer trying to manage client revisions or a growing agency struggling with project handoffs, this list will provide the tools you need. Combined with the right CRM for consulting, these methods can transform your operations.You'll learn how to identify the root cause of your operational headaches and implement targeted changes that deliver immediate results, helping you reclaim time and boost your bottom line. Let's explore how you can start refining your operations today.

1. Lean Six Sigma

Are your projects consistently running over budget and past deadlines, all while quality suffers? It often feels like you're playing a game of whack-a-mole, fixing one problem only for another to pop up. This is a common pain point where teams struggle to balance speed, cost, and quality. Lean Six Sigma offers a powerful, integrated solution by tackling the root causes of these issues head-on.

Lean Six Sigma is a hybrid methodology that combines Lean's focus on eliminating waste with Six Sigma's data-driven approach to reducing defects and process variation. This dual-pronged strategy is one of the most effective business process improvement methods because it doesn't just make processes faster; it makes them better and more reliable. By identifying and removing non-value-added activities (waste) and using statistical analysis to pinpoint sources of error, organizations can achieve dramatic improvements in efficiency and customer satisfaction.

How Lean Six Sigma Works

The methodology primarily follows the five-stage DMAIC framework: Define, Measure, Analyze, Improve, and Control. This structured cycle ensures that improvements are based on verifiable data, not guesswork. For instance, Motorola, a pioneer of the methodology, famously used it to reduce its manufacturing defect rates by an astonishing 99.7%. This wasn't achieved by simply telling people to "work harder," but by systematically analyzing every step, identifying variation, and implementing controls to sustain the gains.

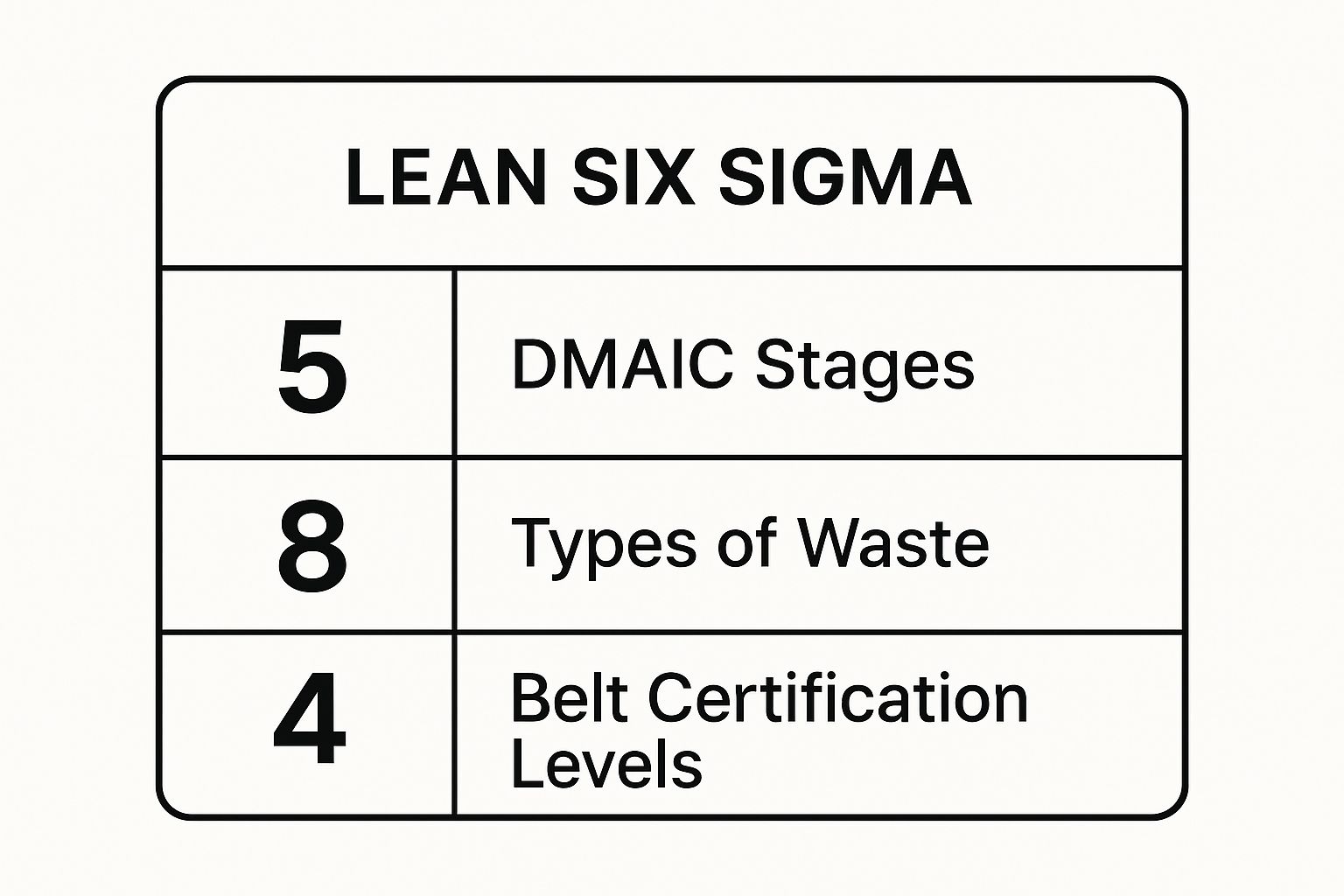

The infographic below summarizes the core components of the Lean Six Sigma framework, including the DMAIC stages, the eight types of waste it targets, and the common certification levels.

This visual highlights how Lean Six Sigma provides a structured path (DMAIC), a clear enemy (the 8 wastes), and a system for building expertise (belt levels), making it a comprehensive and scalable approach.

2. Kaizen

Does your team feel that process improvement is a massive, once-a-year project that requires shutting everything down? This often leads to improvement fatigue, where initiatives lose momentum because they feel too disruptive and overwhelming. The result is that small, everyday inefficiencies are ignored until they snowball into major problems. Kaizen offers a sustainable alternative by embedding improvement into your daily culture.

Kaizen is a Japanese philosophy centered on continuous, incremental improvement involving every employee, from the C-suite to the front line. Instead of seeking a single, revolutionary change, it focuses on making small, ongoing adjustments. This approach is one of the most powerful business process improvement methods because it empowers teams to solve problems as they arise, fostering a culture of ownership and constant refinement. It reduces resistance to change by making improvements manageable and part of the regular workflow, rather than a separate, intimidating project.

How Kaizen Works

The core of Kaizen is the belief that big results come from many small changes accumulated over time. It often utilizes tools like the PDCA (Plan-Do-Check-Act) cycle to test ideas on a small scale before wider implementation. Real-World Use Case: Virginia Mason Medical Center Virginia Mason Medical Center used Kaizen principles to redesign its patient flow, successfully reducing average wait times by an astonishing 85%. They didn't do this with a single, massive overhaul. Instead, they systematically identified and eliminated small delays—like searching for supplies or redundant paperwork—in the patient journey. This focus on continuous, small improvements created a ripple effect, dramatically enhancing the patient experience and operational efficiency.

This shows that Kaizen isn't just for manufacturing. It's a powerful tool for service-based organizations to deliver better outcomes by focusing on incremental daily progress.

For service businesses, applying Kaizen principles to your client onboarding process can eliminate friction and improve the customer experience from day one.

3. Business Process Reengineering (BPR)

Does it feel like your team is patching up a fundamentally broken system? You make small tweaks, but core problems like slow turnarounds, high operational costs, and frustrated customers persist. This is a common pain point where incremental changes are no longer enough. Business Process Reengineering (BPR) offers a radical solution by starting over, fundamentally rethinking and redesigning processes from the ground up for dramatic performance gains.

Business Process Reengineering is an ambitious approach that challenges deep-seated assumptions and focuses on what a process should be, not just improving what it currently is. As one of the most transformative business process improvement methods, BPR is not about making small adjustments; it's about achieving quantum leaps in performance. By wiping the slate clean, organizations can redesign workflows around modern technology and customer needs, leading to massive improvements in cost, quality, service, and speed.

How Business Process Reengineering Works

Instead of tweaking existing steps, BPR starts with a desired outcome and works backward to build the most effective path to achieve it. This "clean sheet" approach requires strong executive leadership and a willingness to challenge every rule and assumption. For example, Ford Motor Company used BPR to overhaul its accounts payable department. Instead of just speeding up the old process, they reengineered it so that payment was triggered automatically upon receipt of goods, slashing head-count by 75% and eliminating invoice mismatches.

BPR is most effective for core processes that are critical to competitive advantage but are deeply inefficient or outdated. It follows a general flow: Prepare, Identify, Redesign, and Transition. The goal is to move from fragmented, department-siloed tasks to integrated, cross-functional processes. This requires a significant investment in change management to guide the workforce through a major operational and cultural shift. The focus is on a complete overhaul rather than continuous, minor improvements.

When proposing major process changes to stakeholders, a well-structured project proposal can help you secure buy-in for your BPR initiative.

4. Total Quality Management (TQM)

Does it feel like quality is an afterthought in your organization, a final checkpoint rather than a guiding principle? This often leads to inconsistent customer experiences, rework, and a reactive culture where teams are constantly firefighting. When quality is siloed within a single department, the entire organization misses opportunities for excellence. TQM addresses this by making quality everyone's job.

Total Quality Management (TQM) is a comprehensive philosophy where every process, person, and department is oriented toward delivering and improving quality for the customer. Unlike methods that focus on specific processes, TQM is an organizational culture shift. It stands as one of the most foundational business process improvement methods because it embeds continuous improvement into the company's DNA, fostering long-term customer loyalty and operational stability.

How Total Quality Management Works

TQM operates on the principle that customer satisfaction is the ultimate goal, and this is achieved through the total involvement of all employees. It’s not a one-off project but a continuous effort. Here's a step-by-step approach to get started:

- Gain Leadership Commitment: Secure unwavering support from the top to drive the quality-first culture.

- Form a Quality Council: Create a cross-functional team to oversee the TQM implementation.

- Identify Critical Processes & Customer Needs: Determine which processes have the biggest impact on customer satisfaction. A solid resource management plan helps you allocate your team's time to these high-impact areas.

- Provide Training: Equip all employees with the principles of TQM and problem-solving tools.

- Establish Quality Metrics: Define clear, measurable goals for quality improvement.

- Empower Employees: Give teams the authority to identify and solve quality issues at their source.

- Monitor & Review: Continuously track progress against metrics and refine the approach.

For a deeper look into implementing quality-focused strategies, you can explore more about project quality management on growlio.io. This commitment ensures that quality isn't just a slogan but a measurable, daily practice for everyone.

5. Agile Process Improvement

Is your team stuck in analysis paralysis, spending months planning improvements that are outdated by the time they launch? Many organizations find that traditional, long-cycle improvement projects can't keep pace with a rapidly changing market. This is a critical pain point where rigid, top-down approaches fail to deliver timely value. Agile Process Improvement offers a dynamic, iterative solution by breaking down large initiatives into small, manageable sprints.

Agile Process Improvement adapts principles from software development to enhance business operations. It prioritizes flexibility, customer collaboration, and rapid, incremental delivery over extensive upfront planning. This makes it one of the most responsive business process improvement methods available, as it allows teams to test ideas, gather feedback, and pivot quickly. Instead of aiming for a single, perfect solution in the distant future, Agile focuses on delivering tangible value through short, focused cycles, ensuring improvements are relevant and effective.

How Agile Process Improvement Works

The methodology operates in short cycles called "sprints," typically lasting one to four weeks. Each sprint is a self-contained project focused on delivering a specific, working improvement. For example, when you want to improve your client onboarding process, you can manage it in an Agile way within a tool like growlio.

- Define the Sprint Goal: Example: "Reduce new client setup time by 10%."

- Build the Backlog: List all tasks needed, like "Create template welcome email," "Build project setup checklist," "Automate initial folder creation."

- Run the Sprint: Your team works on these tasks for 2 weeks.

- Ship the Improvement: At the end of the sprint, the new, faster onboarding process is live.

- Review and Adapt: In a retrospective, the team discusses what worked and plans the next sprint.

This iterative approach ensures that resources are always directed toward the most valuable activities, a stark contrast to waterfall-style projects where priorities can become misaligned over time. For those looking to implement this, understanding how to structure these short cycles is critical. You can get more insights on creating project timelines that are ideal for Agile teams on growlio.io.

6. Value Stream Mapping

Does your team ever feel like they're working hard, but projects still get stuck in bottlenecks you can't quite pinpoint? It’s a frustrating scenario where information or materials seem to vanish into a black hole between steps, causing delays and inflating costs. Value Stream Mapping (VSM) provides the clarity you need by creating a visual blueprint of your entire process, from start to finish.

Value Stream Mapping is a lean management technique used to analyze the flow of materials and information required to bring a product or service to a consumer. It's one of the most insightful business process improvement methods because it forces you to see the process from the customer's perspective, highlighting every step that adds value and, more importantly, every step that doesn't. By mapping both the "current state" and designing a "future state," VSM provides a clear roadmap for eliminating waste and improving flow.

How Value Stream Mapping Works

The process involves physically walking through the process (a "gemba walk") to observe and document every action, delay, and piece of information. This isn't just about drawing boxes on a whiteboard; it’s about capturing real-world data like cycle times, wait times, and inventory levels. For example, industrial equipment manufacturer Lantech used VSM to analyze its production line. They discovered excessive inventory and long lead times. By redesigning their process flow based on the VSM, they dramatically improved inventory turns from just 3 to 14 per year.

The following video from the Lean Enterprise Institute, founded by VSM pioneer John Shook, offers a great introduction to the core concepts.

This visual approach makes it easier for everyone, from frontline workers to executives, to see the sources of waste and collaborate on solutions. It turns abstract problems into a concrete map you can act on.

7. Process Mining

Do your operational dashboards show perfect processes, yet reality is a mess of delays, bottlenecks, and unhappy customers? You think a process flows from A to B to C, but in practice, it zigs, zags, and sometimes goes backward. This gap between the "as-designed" and the "as-is" process is a major pain point, leading to hidden inefficiencies. Process Mining provides an MRI for your operations, revealing what’s actually happening under the surface.

Process Mining is a data-driven discipline that uses event logs from your IT systems (like your CRM, ERP, or project management software) to automatically discover, monitor, and improve real-life processes. It's one of the most transformative business process improvement methods because it replaces assumptions and manual interviews with objective, fact-based evidence. Instead of guessing where the problems are, you can see every deviation, delay, and rework loop, allowing you to target improvements with surgical precision.

How Process Mining Works

This methodology uses specialized software to analyze digital footprints, or event data, that your systems generate every day. Each event log typically contains a case ID (e.g., an order number), an activity (e.g., "Invoice Approved"), and a timestamp. By stitching these data points together, the software creates a dynamic, visual process map that shows exactly how work flows. For example, Siemens used this approach to analyze its IT service management. By visualizing the actual incident resolution paths, they identified non-standard deviations and bottlenecks, leading to a 30% improvement in process efficiency.

The power of Process Mining lies in its ability to turn raw data into an interactive, visual story of your process. You can see the most common paths, the frequency of exceptions, and the time spent between steps, providing undeniable proof of where your process is breaking down.

8. Root Cause Analysis (RCA)

Does your team ever feel like they are constantly fighting the same fires? You solve a problem, only for it to reappear weeks later, consuming valuable time and resources. This frustrating cycle often stems from treating symptoms instead of the underlying disease. Root Cause Analysis (RCA) offers a cure by providing a systematic way to dig beneath the surface and uncover the fundamental reason a problem occurs.

Root Cause Analysis is a problem-solving methodology designed to identify the true origin of an issue. Instead of stopping at the immediate, obvious cause, it pushes teams to ask "why" repeatedly until the foundational breakdown is revealed. This makes it one of the most essential business process improvement methods because it prevents problem recurrence. By fixing the core issue, you create a more resilient and efficient system, ensuring that solutions are permanent rather than temporary patches.

How Root Cause Analysis Works

RCA isn't a single technique but a collection of tools, with the "5 Whys" and the Fishbone (Ishikawa) diagram being the most prominent. Here's a step-by-step guide using the 5 Whys:

- Define the Problem: Be specific. Example: "The final client report was delivered two days late."

- Ask the First "Why?": Why was it late? "Because the final data from the analytics team was delayed."

- Ask the Second "Why?": Why was the data delayed? "Because the data query took 12 hours to run, not the usual 2."

- Ask the Third "Why?": Why did the query take so long? "Because it was processing a much larger dataset than anticipated."

- Ask the Fourth "Why?": Why was the dataset so large? "Because a new tracking script was added last month, but the query wasn't updated to handle the new data volume."

- Identify the Root Cause: The root cause isn't a slow team; it's an outdated query that wasn't updated as part of the process for adding new tracking. The solution is to update the query and, more importantly, update the process to include a query review step whenever new tracking is implemented.

This structured approach ensures that improvement efforts are directed at the correct target and prevents the same issues from derailing future projects.

9. Design Thinking for Process Innovation

Are your process improvements technically sound but failing to gain traction with the people who actually use them? This often happens when solutions are developed in a vacuum, ignoring the human element and creating processes that are logical but frustrating in practice. This is a common pain point where efficiency gains on paper don't translate to reality because user experience is an afterthought. Design Thinking flips the script by putting human needs at the very center of the improvement process.

Design Thinking is a human-centered approach to innovation that uses an iterative, non-linear framework to understand users, challenge assumptions, and redefine problems. Unlike more rigid, data-heavy business process improvement methods, it prioritizes empathy and creativity to develop solutions that are not just efficient but also intuitive and desirable for the end-user. By focusing on the people behind the process, organizations can uncover hidden needs and create improvements that people genuinely want to adopt.

This visual highlights the fluid, cyclical nature of the framework. It’s not a strict, linear path but a series of overlapping stages that encourage continuous learning and refinement, ensuring the final process is deeply aligned with user needs and context.

How Design Thinking Works

The methodology typically follows a five-stage model: Empathize, Define, Ideate, Prototype, and Test. It begins with developing a deep, empathetic understanding of your users' challenges. For instance, Bank of America used this method to create its "Keep the Change" program. Instead of just analyzing spending data, they observed customers' real-life saving habits and struggles. This empathetic insight led to an innovative solution that automatically rounded up debit card purchases and transferred the difference to a savings account, addressing a core user need in a seamless way. This user-centric innovation resulted in millions of new accounts.

Pro Tip: Create "empathy maps" during the initial stage. This visual tool helps your team collaboratively document what a user is thinking, feeling, saying, and doing in relation to the process. It forces the team to step outside their own assumptions and build a shared understanding of the user's true experience, leading to more meaningful and impactful process innovations.

To get started with Design Thinking, begin by conducting interviews and observations with the people involved in your process. Map their journey, identify their pain points, and then start brainstorming creative solutions.

Business Process Improvement Methods Comparison

| Methodology | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Lean Six Sigma | Moderate to High - Structured DMAIC, requires certified belts and strong leadership | High - Training, data analysis tools, time investment | Waste reduction, process efficiency, quality improvement | Complex processes needing waste elimination & quality control | Combines Lean speed with Six Sigma quality; measurable ROI |

| Kaizen | Low - Continuous small changes, employee-driven | Low - Focus on employee engagement and suggestions | Incremental improvements, quick wins | Any process/department with culture open to change | Low cost, builds engagement, sustainable improvement culture |

| Business Process Reengineering (BPR) | High - Radical redesign, cross-functional teams, change management | Very High - Significant resources, technology, leadership | Dramatic performance improvements, cost reductions | Processes needing total transformation or obsolete workflows | Potential for breakthrough improvements, technology leverage |

| Total Quality Management (TQM) | Moderate to High - Organization-wide effort, cultural change | High - Training, quality systems, ongoing commitment | Improved customer satisfaction, quality culture | Organizations focused on long-term quality and customer focus | Comprehensive quality focus; engages all employees |

| Agile Process Improvement | Moderate - Iterative cycles, requires facilitation | Moderate - Small teams, regular collaboration | Faster time to value, adaptive improvements | Dynamic environments requiring rapid, flexible changes | Fast results, stakeholder involvement, reduced risk |

| Value Stream Mapping | Moderate - Requires detailed process mapping | Moderate - Involvement of workforce, mapping tools | Clear visualization of waste, process flow efficiency | Analyzing and improving material/info flow in processes | Visualizes inefficiencies; aligns teams; quantifies waste |

| Process Mining | High - Requires expertise, digital event logs | High - Specialized software, data quality efforts | Data-driven insights, bottleneck identification | Processes with rich digital footprints | Objective process behavior discovery; continuous monitoring |

| Root Cause Analysis (RCA) | Low to Moderate - Structured investigation methods | Moderate - Skilled facilitators, team involvement | Identifies underlying causes, prevents recurrence | Problem-solving in complex issue resolution | Addresses root causes; cost-effective; builds organizational learning |

| Design Thinking for Process Innovation | Moderate - Iterative, requires design facilitation | Moderate - User research, prototyping resources | User-friendly, innovative, and effective processes | Human-centered, user experience-focused innovations | Encourages creativity; reduces risk via iterative testing |

Stop Patching Broken Processes. Start Building Better Ones with growlio.

Throughout this guide, we've explored a powerful arsenal of business process improvement methods, from the disciplined precision of Lean Six Sigma to the human-centered innovation of Design Thinking. We’ve seen how Kaizen drives daily incremental gains, how Business Process Reengineering (BPR) can radically transform core operations, and how tools like Value Stream Mapping and Process Mining provide the data-driven clarity needed to see what's truly happening within your workflows.

The common thread weaving through all these methodologies is a commitment to moving beyond temporary fixes. It’s about ending the cycle of patching leaky, inefficient systems and instead, building robust, streamlined processes designed for growth and resilience. Each method offers a unique lens, but they all share the same goal: eliminating waste, reducing errors, and creating more value for your clients and your team.

Your Path from Theory to Action

Mastering these concepts is not an academic exercise; it's a strategic imperative. For creative agencies, it means faster project turnarounds and more capacity for client work. For consultants and freelancers, it translates to more predictable revenue and less time spent on administrative churn. For software teams, it's the key to shipping better products, faster.

So, where do you begin? Don't try to implement everything at once. The first step is to choose a starting point that addresses your most significant pain point.

- Feeling overwhelmed by daily inefficiencies? Start with Kaizen. Ask your team this week: "What is one small thing we can change to make our work 1% easier?"

- Struggling with project delays and bottlenecks? Use Value Stream Mapping. Sketch out the steps of a recent project from client request to final delivery and identify where work sat idle.

- Dealing with recurring, costly mistakes? Apply Root Cause Analysis (RCA). Instead of just fixing the latest error, use the "5 Whys" technique to uncover the systemic issue that allowed it to happen.

The true value of embracing business process improvement methods lies in creating a culture of continuous evolution. It’s about empowering your team to not just do the work, but to actively improve the work. By adopting this mindset, you transform your operations from a source of friction into a competitive advantage that fuels profitability, client satisfaction, and sustainable growth. The goal isn't just to fix what's broken today, but to build a framework that prevents processes from breaking tomorrow.

As you implement these business process improvement methods and gain efficiency, you'll likely see increased profitability. Make sure you're prepared for the financial side by understanding your self-employment tax obligations and setting aside the right amount from your improved cash flow.

Ready to turn these methods into reality? The principles of process improvement are powerful, but they need a platform to truly come alive. Start your free growlio account today and get the visibility and control you need to implement frameworks like Agile and Kaizen, turning theory into action. Stop managing tasks in spreadsheets and start building streamlined, repeatable workflows.